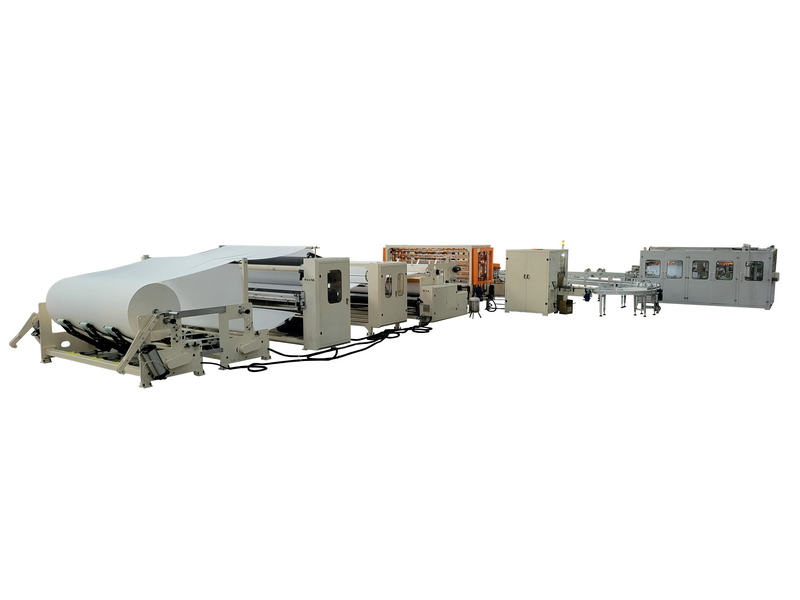

Romania no need hand touch high speed lamination small toilet paper roll making color printing kitchen towel machine production line

Advanced Paper Towel Converting System – Energy Efficient & Easy Operation

Professional Kitchen Roll Machine – Trusted by South American Suppliers

Technical performance characteristic:

This production line consists of :

1. XY-TQ-B Automatic small kitchen towel and toilet paper making machine

2. XY-203 Log roll paper accumulator

3. XY-AI-280 High speed kitchen paper and toilet roll log saw Cutting Machine

4. XY-AI-398D Full automatic 4-48 rolls small kitchen towel and toilet paper packing machine

From jumbo roll paper into the finished rollers, the whole line work smoothly and run stable, saving the labor cost and reducing the labor strength. It’s best choice for the producing kitchen towel and toilet paper products.

1. XY-TQ-B Automatic kitchen towel and toilet paper rewinding machine

Feature and Function

Automated Core Feeding & Log Handling

Features an automatic core feeding system with integrated log pusher, enabling seamless rewinding of new logs without manual intervention.

Synchronized Edge-Trimming & Sealing

Performs edge-trimming, core feeding, glue spraying, and sealing in one synchronized cycle. Leaves a 10-18mm tail for easy rewinding, minimizing material waste and lowering production costs.

Smart PLC Control & User-Friendly Interface

Equipped with advanced PLC programmable control technology. Operates via an intuitive touch-screen HMI (Human-Machine Interface) with real-time data display, parameter settings, and fault diagnostics.

High-Precision Spiral Cutting System

Utilizes 4 high-accuracy spiral knives for clean perforation with minimal noise. Includes a gearbox for extended cutting range and versatility.

Pneumatic Jumbo Roll Handling

Three horizontal back stands with pneumatic loading and wide flat driving belts. Each jumbo roll is independently adjustable for precise alignment.

Premium Embossing Unit

Point-to-point embossing rollers ensure perfect layer alignment, delivering ultra-soft paper with sharp, consistent patterns.

Safe & Easy Operation

Jogging switches simplify paper threading, enhancing operator safety and convenience.

Product Parameters

| Machine Model | XY-TQ-B |

| Jumbo Roll Max Width | 1200-3000mm (Depends on the model) |

| Jumbo Roll Diameter | Φ1200mm(Other size can be specified) |

| Jumbo Roll Inner Diameter | 3inches(76.2mm) (Other size can be specified) |

| Perforation Distance | 4 anvil Blades(90-140mm)(Other size can be specified) |

| Finished Product Diameter | Φ90~φ300mm |

| Finished Product Core Diameter | φ38~φ90mm |

| Production Speed | 180~230m/min |

| Program Controller | PLC( INVT ) |

| Unwind Stands | 2 Stands(Need to be specified) |

| Pneumatic System | 3HP Air Compressor, Minimum Pressure: 5kg/cm 2Pa(Provide by user) |

| Main Power | 40KW 380V 50HZ (Depends on the model) |

| Dimension | 7000*4000*1900(L*W*H) |

| Weight | About 7T |

| Edge-Line Embossing | Steel to steel (Pneumatic Control) |

| Full Embossment | Steel to rubber. |

2. XY-203 Log roll paper accumulator

Function: To make glue laminated log paper roll dry before cutting and packing, so to get a better effect.

| Machine Model | XY-203 Log Accumulator |

| Log Width | 1750~2800mm(Other size can be specified) |

| Log Diameter | Φ95mm~Φ140mm |

| Log Standings | 65 Logs |

| Accumulate speed | 20 logs/min |

| Log Qty | 60 logs(need to be ordered) |

| Overall Dimensions | 4000*3000*5500mm |

| Programming Controller | PLC(Delta) |

3. XY-AI-280 Full Automatic kitchen paper and toilet roll log saw Cutting Machine

| Name | Full Automatic kitchen paper and toilet roll log saw Cutting Machine |

| Cutting blade | log saw blade(size 610*68.3*3.8mm) |

| Finished Product length | 250mm |

| Finished Product Diameter | 95-140 mm |

| Production Speed | 180-200 rolls/min |

| Toilet log length | 2200 mm/2800 mm |

| Finished Products | Small Toilet Paper Roll and kitchen towel |

| Application | Paper roll Cutting Machine |

| Function | Cut Toilet Paper Roll and kitchen towel |

| Type | Paper Roll Cutting Machine |

4. XY-AI-398D Full automatic 48 rolls kitchen towel and toilet paper packing machine

Characteristics:

1. Temperature control system: The temperature is controlled by an independent PID, using copper block heating and AC control mode, which has strong adaptability to the corona quality of the packaging bag and effectively avoids the disadvantages of false sealing;

2. The base paper adopts a single-channel feeding, which is efficient and beautifully formed;

3. Single-layer and double-layer free switching options, simple and convenient switching.

4. The sealing pressure plate and the side guard plate cooperate to meet the user's stringent requirements for packaging tightness.

5. The servo-controlled dynamic bag-opening and bag-supporting mechanism effectively improves the stability of bag opening and bagging.

6. Various packaging specifications and sizes can be freely and electrically adjusted to quickly complete the conversion.

7. From bagging to sealing and forming, the side guard plate is protected throughout the process to effectively avoid bag breakage.

| Model | XY-AI-398D |

| Air supply | 0.6Mpa |

| Power supply | 7.5Kw 380V 50HZ |

| Speed | 8-20 bundling bag/min |

| Single roll size | Diameter:Ø90-120mm Height:90-140mm |

| Bundling Size | L(270-600)*W(180-240)*H(90-120) mm

12,18,30,48 rolls/bundling bag |

| Machine size | |

Q: Are you trading company or manufacturer

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 60-90 days if the goods are not in stock, it is according to

quantity.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

After Sales Service

(1), All our machine will have Two years guarantee

(2), Within two year after receiving our machines, Under right operation and non-artificial reasons, If there are any damaged parts or accessories, We will replace them by DHL or Fedex immediately FREE OF CHARGE.

(3), After two year warranty, Spare parts and damaged parts will be charged at cost price. If there is something wrong with the machine, We are responsible to solve this problem soonest, and help customers to restore production as soon as possible.

(4), After the machines arrive, the sellers shall send technician to install the production line(if need). And the buyer shall pay their round-trip air tickets from China factory to buyer's factory, the charge of visa, food ,transportations and accommodation in buyer's city.